Oil separators shall be Rockford Separators as manufactured by Rockford Separators, Inc., Rockford, Illinois, and as noted on plans.

SPECIFICATIONS

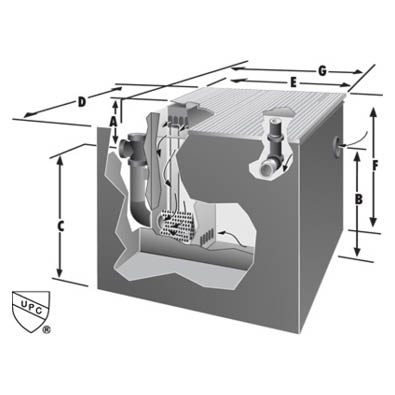

Furnish ____Rockford Model OSTL-____-____gallon integral storage compartment, all-welded ____ 10 gauge steel separators, ____g.p.m. intermittent flow ____” (tapped) (hubbed) inlet and outlet, ____” tapped internal vent connection ____” adjustable oil draw-off, visible double-wall outside trap seal, non-removable separator screen with easily removable filter screen, removable 3/16″ nonskid diamond treadplate cover(s) for flush-with-floor installation for pedestrian traffic, or reinforced for ____ (light) (heavy) traffic, cover(s) secured with stainless steel flat head screws, extra-heavy leakproof gasket. OPEX® Shop Coat coating (resistant to oil, grease and cutting oils) inside and bituminous coating outside.

OPTIONAL FEATURES

Anchor flange, filter media, sediment basket, integral extension, acid-resistant epoxy coating, anodes, coalescing pack, high level sensor and alarm, double-wall construction, with or without leak detection.

NOTE

These are lighter gauge oil separator

TOTAL/UNCONFINED/UNRESTRICTED/OSHA

Recommended Top Access to be able to observe and clean the entire fluid surface in all chambers down to the bottom of the unit.

LARGER UNITS AVAILABLE.

Call for specifications.

* Anchor flange requires 3″ extension.

• 6″ & larger – companion flange connection.

+ Length is the distance from inlet to outlet ends.

† Any smaller size storage compartment may be ordered P.O.A.

Example: OSTL-5636 (Model No.) – 50 (Oil Storage)

Standard storage supplied unless specified otherwise